Summary: Timber mats work because the timbers accept and spread the load of heavy machinery onto the underlying ground. If timbers aren’t sound – if they contain defects – or if there isn’t wood where there should be, then the timber mats can’t do their job.

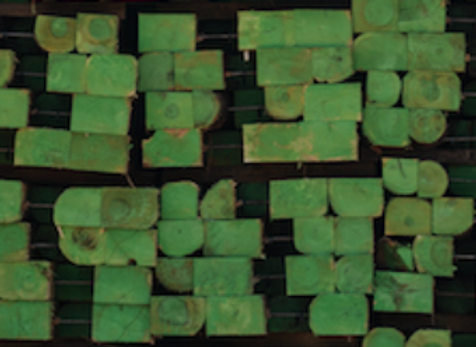

Common mat defects include wane*, bark, voids, splits, and rot. They all matter because it’s wood fiber that provides the strength.

For example, bark has almost no bearing capacity. Voids – gaps where there should be wood but isn’t – are air, not wood.* Bark and voids are problematic because bolts can loosen and compromise the strength of the mat.

All this uncertainty in mat quality means uncertain mat performance.

Conclusion: Not every mat use needs to have reliable results. For those uses that do need reliable results consider sourcing mats that are uniformly manufactured, with no defects, and manufactured from species with strong working characteristics.

- Forest Products Laboratory, United States Forest Service . Wood as an Engineering Material. Definitions: “Wane: Bark or lack of wood from any cause on edge or corner of a piece”

** Forest Products Laboratory, United States Forest Service May 2006. Article No. 10204

*** For simplicity, engineers view timber mats as square units though they rarely are. A round cross-section isn’t as stable as a square section.