This post – “What Kind Of Wood Is Used For Crane Mats?” – was created on January 22, 2026

Most crane mats use mixed hardwood, oak, or Douglas fir, with big swings in strength and lifespan.

Eucalyptus crane mats use a known, stronger species so you can right-size thickness and cut total cost.

Choosing the right wood species protects your schedule, safety record, and budget on every lift.

Contractors ask this all the time: What kind of wood is used for crane mats. Does the wood really matter for cost and safety?

Yes. Crane mat wood species determine strength, lifespan, and how many mats you need to move on every project.

Common Woods Used For Crane Mats

Most conventional crane mats are built from a mix of species that change as supply shifts. Typical options include:

Mixed hardwood, historically including oak and other dense hardwoods, but now many different species with various timbers grade.

All oak crane mats for higher strength, when logs are available and priced reasonably.

Douglas fir, hemlock, or pine crane mats where geography, availability, or price drives decisions.

However, mixed hardwood mats can hide big differences in strength from timber to timber, which makes engineering tricky and often requires very careful engineering. Gone are the days when every crane mat was the same. That ended almost 10 years ago.

Where Eucalyptus Crane Mats Fit

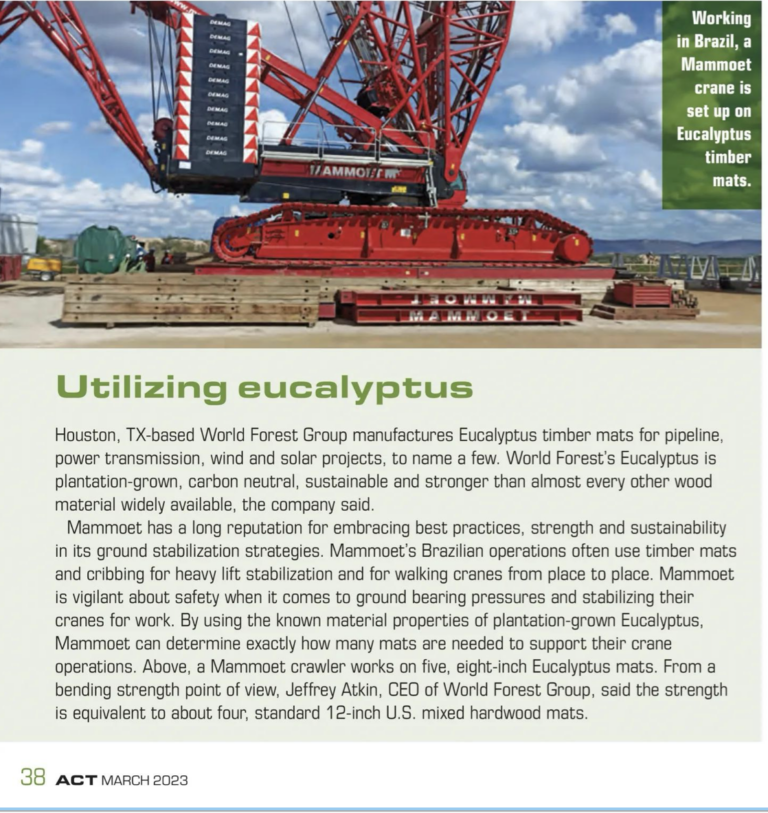

Eucalyptus crane mats use a single clonal species instead of whatever shows up in the mixed hardwood stream. This gives you standardized properties and more predictable strength under real loads.

Independent testing and field data show Eucalyptus is significantly stronger in bending, shear, and MOE than typical mixed hardwood or oak. That strength gives you more safety margin. It also gives you another option: Using a thinner mat. Strength-adjusted Eucalyptus crane mats can often be thinner and lighter. Yet they’ll match or beat conventional 12 inch mixed hardwood mats in bending strength.

For a deeper overview, you can review the basics of Eucalyptus timber mats in the learning module.

Why Species Choice Changes Cost

Wood species choice for crane mats shows up fast in freight, handling, and replacement costs. Stronger, standardized species like Eucalyptus gets you longer life and much lower daily depreciation.

It also lets you match mat thickness to actual strength instead of rule-of-thumb inches.

This usually means:

Fewer mats for the same lifts because each mat has more strength.

More mats per truck, since Eucalyptus is lighter than mixed hardwoods.

You often move thinner Eucalyptus crane mats instead of thicker mixed hardwood.

Lower total cost of ownership as longer-lived mats reduce replacement cycles and re-handling.

Independent discussions of crane mat quality and species variability back up the importance of known wood properties when you are planning lifts and access.

Why Carbon Neutral Eucalyptus Timber Mats Matter Even Now

If it’s important to your job….

Species choice also affects carbon and freight, which ultimately drive your project cost. Stronger Eucalyptus crane mats can be thinner and lighter, so you put more mats on every truck and cut total truck moves.

As a result, you burn less fuel, handle fewer pieces, and reduce both emissions and operating cost on big powerline, renewable, and civil jobs. A broader perspective on how Eucalyptus timber mats support lower-carbon, lower-cost logistics is worth reading.

Next Steps For Your Project

If crane mat wood species is a headache on your current bid, it may help to step back and look at Eucalyptus crane mat case studies. When you compare options, consider required bending strength, expected life, freight lanes, and how many mats you really need to move.

World Forest Group can help you right-size Eucalyptus crane mats for your specific lifts so you control safety, carbon, and total cost instead of chasing today’s mixed hardwood supply. For a specific project, contact the team or request a quote.