Longevity was revised January 6, 2026

-

Eucalyptus mats routinely outlast comparable mixed hardwood mats, especially under wet–dry, heavy-traffic conditions.

-

Square, timbers from a single plantation grown species. Combine with precision manufacturing and you get longer life.

-

Handling, local conditions, and use type still matter, but starting with better materials shifts longevity in your favor.

Longevity

“How long do your mats last?” is one of the first questions contractors, owners, and rental fleets ask about Eucalyptus crane mats, because longevity directly drives total cost of ownership. In real projects with wet–dry cycles, tracked machines around 90,000–100,000 lbs, and regular traffic, Eucalyptus mats have shown multiple years of reliable service and typically outperform comparable mixed hardwood mats.

Eucalyptus timber mats in rental fleets across the East Coast regularly come back as a majority Grade A, with some Grade B, even two or three years after purchase. That’s not what most people expect from “wooden” mats. That longer usable life is the result of better raw material, square geometry, and a repeatable manufacturing process rather than luck.

Video Highlights: Eucalyptus Mats Over Time

For a quick look at how Eucalyptus mats age in the real world, watch the first video below, which shows rejected mats after more than six years of daily use at our manufacturing facility. Even though these mats never met our quality bar for sale, they still held up under constant use. That use included loading, unloading, and site traffic far better than a typical mixed hardwood mat would.

The additional videos show the life cycle of a mat, how mats look outside the warehouse after long service, and a simple “knife test” that tests Eucalyptus timbers penetration years after installation. Together they give a visual answer to the longevity question that numbers alone cannot.

Why Square Timbers Last Longer and Contribute to Mat Longevity

Longevity starts with geometry. Square timbers hold together better. Add in no wane, no rot pockets, no bark, and no air, and more of the mat’s cross-section is strong Eucalyptus that actually carries load. When you buy a mat with round-ish, log-like timbers, you are really buying air. “Air” includes voids, bark, and sapwood you cannot use—and those weak zones fail first under heavy equipment.

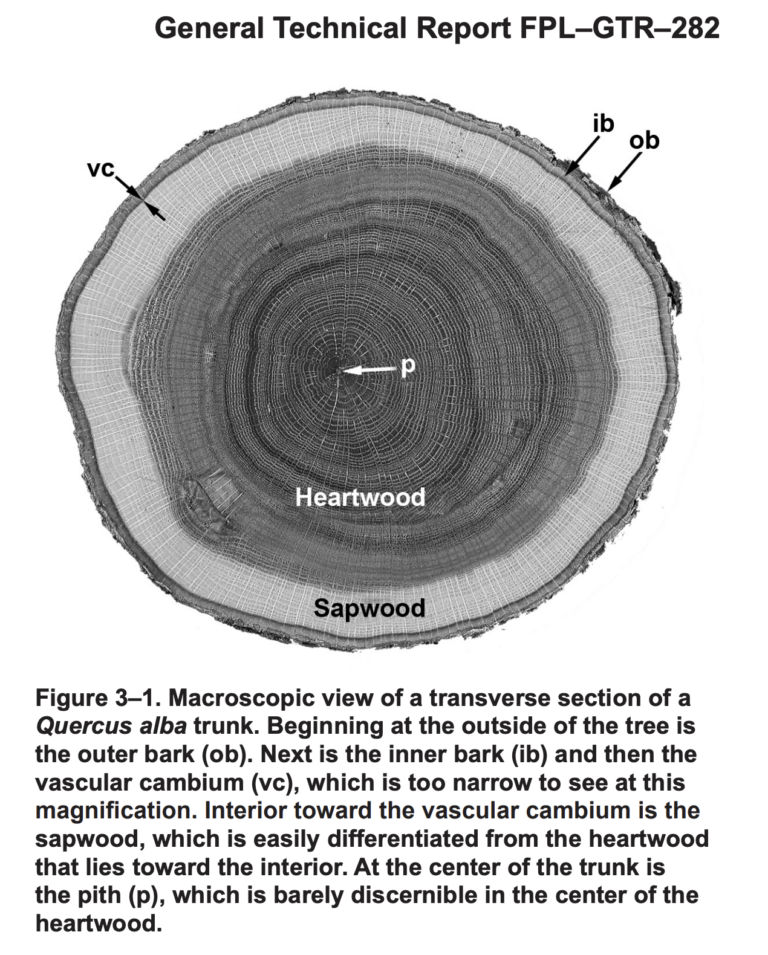

The U.S. Forest Service’s “Wood as an Engineering Material” shows clearly that heartwood is the part of the tree evolved for structural performance. Sapwood, bark, and wane serve other biological functions. By insisting on square, solid timbers, Eucalyptus mats convert more of each board foot into usable strength, which helps them last longer under the same conditions.

Manufacturing Process + Mat Integrity = Mat Longevity

Material alone is not enough; the precision manufacturing process keeps quality consistent from mat to mat. We reject timbers that do not meet geometry or quality criteria. The mats you receive are built from better-than-average pieces rather than whatever happens to come off a saw that day.

End plates and standardized bolts are added to protect critical stress points. They keep the assembly tight as the mat cycles through loading, unloading, and job after job. When bolts bite into dense wood instead of spongy sapwood or wane, they stay tight longer. That maintains the structural integrity of the mat over its service life.

Handling, Local Conditions, And Use Type

How long any mat lasts also depends on what you ask it to do. Careful handling with proper equipment and transition mats can extend life dramatically. Brutal handling, especially side-stabbing with forks or driving dozers straight onto leading edges will eventually damage even the best materials. One customer summed it up well: “Our handling is brutal. World Forest Group’s Eucalyptus mat starts with better materials, square edges, no wane, no bark, no air.”

Local conditions amplify these effects. Wet, rocky, or freezing ground will punish mats, which is why we run drop tests, mine tests, and lab-style testing on thinner 4″, 5″, and 6″ Eucalyptus mats so you can see how they behave under stress. Tired vehicles are much easier on mats than equipment with grousers; in many cases a 6″ or 6.75″ Eucalyptus mat will do the work contractors used to reserve for an 8″ mixed hardwood mat, and a 4″ solid Eucalyptus mat can compete with a five-ply CLT in bending strength.

How This Helps Your Project

Longer mat life reduces replacement cycles, freight, and downtime, which lowers total cost of ownership across a multi-year construction program. When mats keep coming back as majority Grade A after years in rental fleets and on tough jobs, you get more productive hours per mat and fewer surprises in the budget.

Starting with better materials and standardized manufacturing also gives you more predictable performance from project to project, which makes it easier to plan spans, crane positions, and access routes with confidence. For many contractors, that predictability is as valuable as the extra years of life.

For project-specific questions about how long Eucalyptus mats could last in your conditions—or which thickness is right for your loads—request a quote with your typical spans, equipment, and soil types, or contact us to talk through options.

Video Summaries for Longevity

Eucalyptus Mats: A Longer Life

In this short video, see how Eucalyptus timber mats look after years of real-world use at our manufacturing facility—and why square, timbers help them outlast typical mixed hardwood mats.”

Life Cycle of a Mat

This video walks through the life cycle of a Eucalyptus mat, from manufacturing and quality control to years of service in the field and eventual retirement.

Mats-Outside-Warehouse

Here you can see Eucalyptus mats outside the warehouse after extended use, giving a realistic picture of wear, checking, and edge condition over time.

Knife Test 2 Eucalyptus Timber Mats post 42 months

In this ‘knife test,’ we drive a screwdriver into the back side of a rejected Eucalyptus mat after 42 months on the ground to show how dense Eucalyptus continues to resist penetration.