Key Highlights:

- Eucalyptus timber mats outperform oak by 40% in strength and are up to 300% more durable than mixed hardwoods.

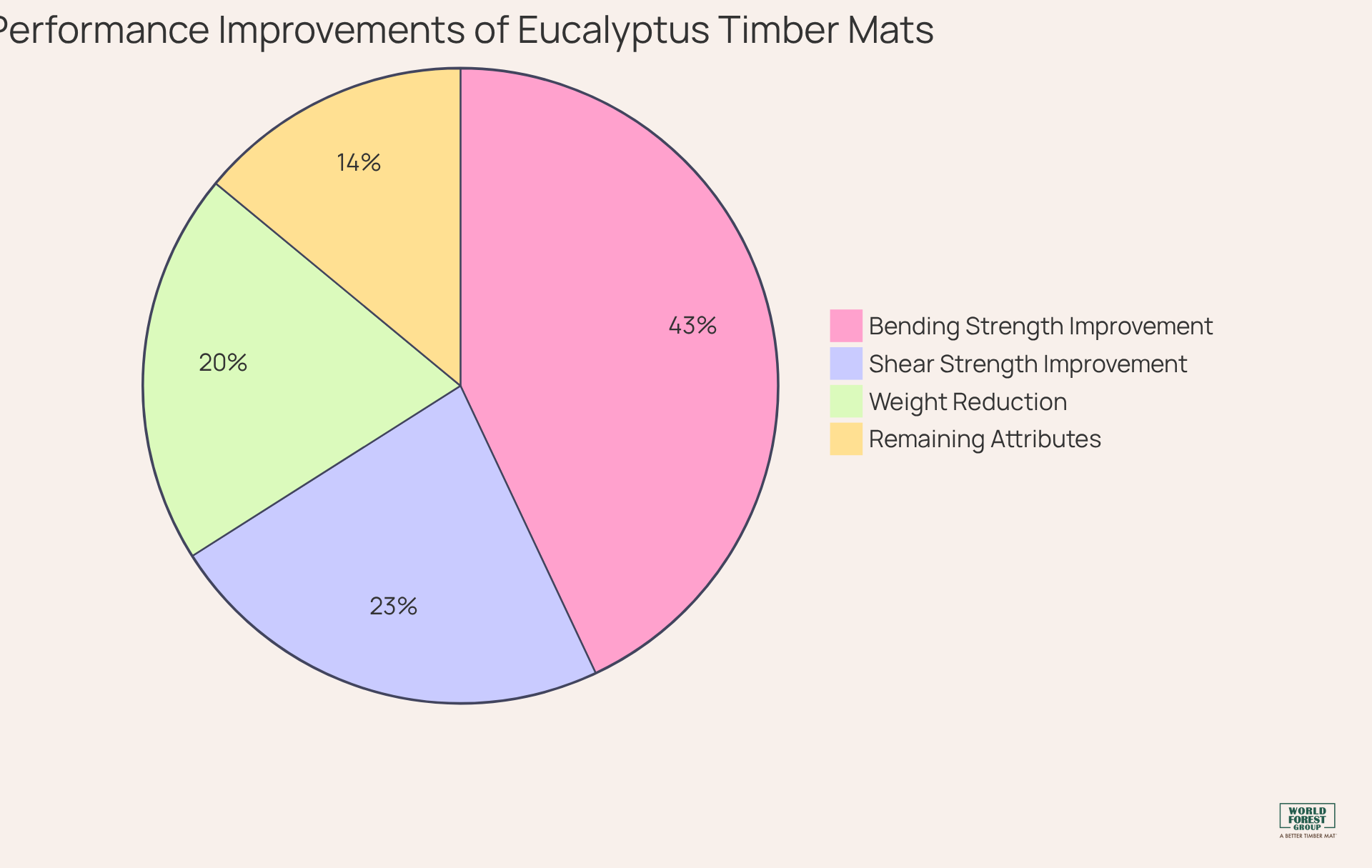

- They offer a 23% increase in shear strength and a 43% enhancement in bending strength compared to Southern Red Oak.

- These mats are lightweight, leading to improved transportation efficiency and reduced logistics costs.

- They maintain integrity under heavy loads, tested with vehicles up to 92,000 lbs, ensuring safety for construction operations.

- Lifespan of 3-4 years with minimal deterioration makes them a long-term investment, offering a total cost of ownership that is 10-40% lower than alternatives.

- Safety features include slip-resistant mats, reducing the risk of accidents in wet conditions.

- Eucalyptus mats are eco-friendly, sourced from rapidly growing plantations that contribute to carbon sequestration.

- They are versatile for various construction projects, providing stable pathways over soft terrain and minimising soil disruption.

- Users report significant cost savings, with some projects saving tens of thousands of dollars due to reduced replacement frequency.

Introduction

Heavy-duty access mats are transforming construction in challenging environments, particularly in boggy terrain where traditional solutions often struggle. These innovative products promise not only enhanced safety and durability but also significant cost savings, making them a compelling choice for contractors.

With a variety of materials available, determining the best option for specific project needs becomes essential. By exploring the unique benefits of heavy-duty access mats, we uncover their critical role in optimizing construction efficiency while effectively addressing the complexities of wet and unstable ground conditions.

World Forest Group Eucalyptus Timber Mats: Superior Strength for Boggy Terrain

World Forest Group’s timber products are engineered for exceptional strength, boasting performance that surpasses oak by 40% and exhibits up to 300% greater durability than various mixed hardwoods. This remarkable resilience renders heavy-duty access mats for boggy terrain particularly effective in marshy environments, where traditional mats often struggle.

When compared to Southern Red Oak, Eucalyptus products showcase:

- A 23% increase in shear strength

- A 43% enhancement in bending strength

- A 20% reduction in weight, thereby improving transportation efficiency

Designed to withstand substantial loads, these mats have been rigorously tested with loaded concrete vehicles weighing up to 92,000 lbs, ensuring safety and reliability for utility contractors and construction firms operating in demanding conditions. Users have reported that these mats maintain their integrity even under harsh circumstances, demonstrating their ability to support significant weight without deterioration.

Moreover, with a lifespan of 3-4 years and minimal to no decline in quality, these products represent a long-term investment, offering a total cost of ownership that is 10-40% lower than alternative options. Their non-slip features further enhance safety on construction sites, making heavy-duty access mats for boggy terrain a robust choice for projects that require dependable temporary solutions, particularly in wet or unstable ground conditions.

Additionally, the standardized product guarantees consistent strength and performance characteristics, providing contractors with peace of mind when relying on trustworthy materials.

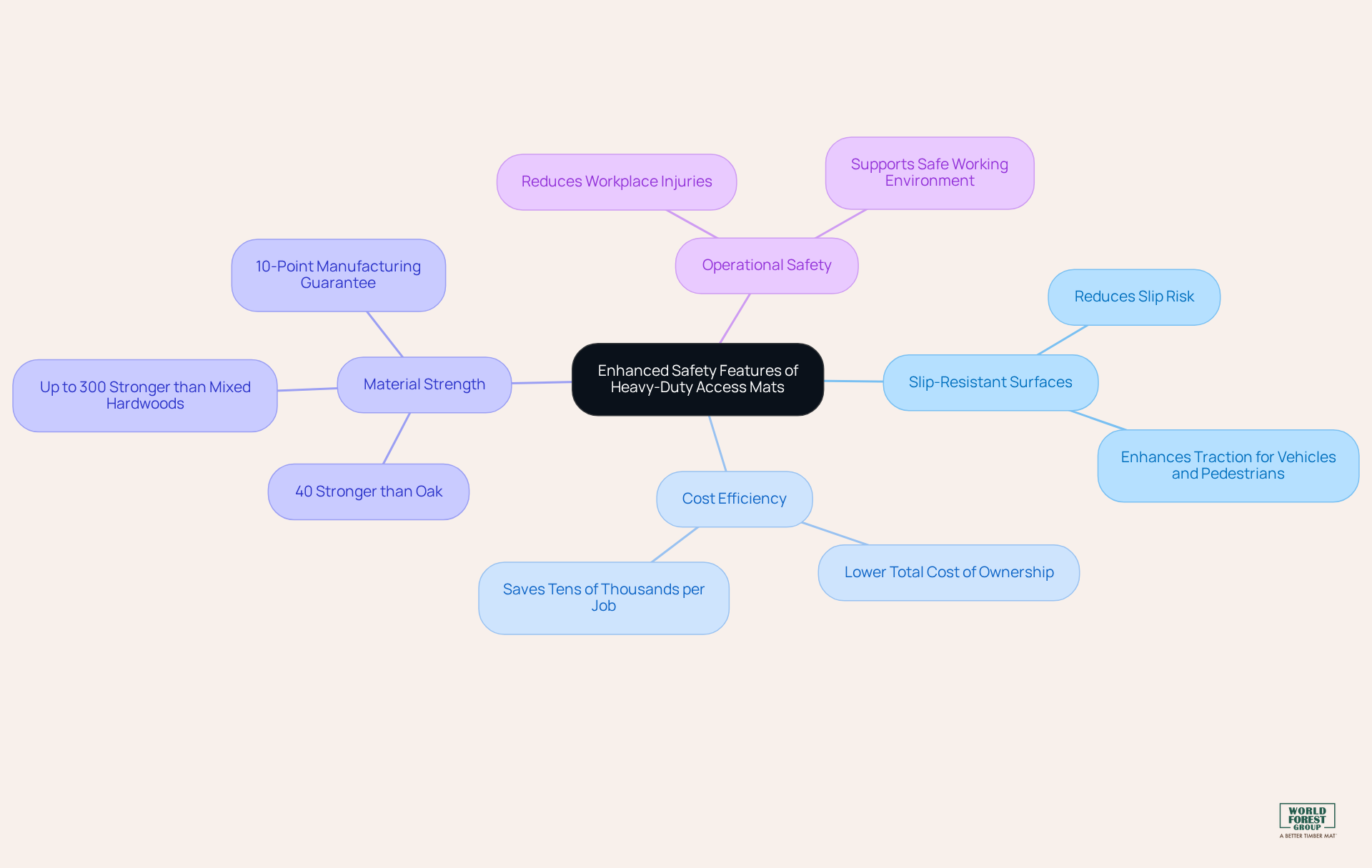

Enhanced Safety Features of Heavy-Duty Access Mats for Construction Sites

Heavy-duty access mats for boggy terrain are designed with advanced safety features, including slip-resistant mats that significantly enhance traction for both vehicles and pedestrians. In wet conditions, where the risk of slipping increases dramatically, heavy-duty access mats for boggy terrain provide a secure, non-slip surface that effectively reduces the likelihood of accidents. This aspect is vital for sustaining a safe working environment, as slips, trips, and falls rank among the leading causes of workplace injuries, resulting in thousands of incidents each year. Safety professionals underscore the necessity of utilizing heavy-duty access mats for boggy terrain in construction, highlighting that appropriate materials can alleviate risks associated with challenging terrains.

For instance, flooring products from World Forest Group not only deliver exceptional strength—40% stronger than oak and up to 300% stronger than various mixed hardwoods—but also possess a lighter weight, making them ideal for use with heavy-duty access mats for boggy terrain to establish secure pathways in muddy or unstable conditions. As one Senior Project Executive from a nationwide EPC remarked, ‘We expect this mat to save us tens of thousands of dollars per job.’ Furthermore, these mats demonstrate a 10-40% lower total cost of ownership compared to conventional alternatives, presenting significant savings for contractors. World Forest Group supports its products with a 10-point Manufacturing Guarantee, ensuring consistent quality and reliability.

By investing in heavy-duty access mats for boggy terrain, companies can substantially enhance operational safety and efficiency, allowing workers to perform their duties without the persistent worry of slipping or falling. Request a quote today to explore how these mats can elevate your project.

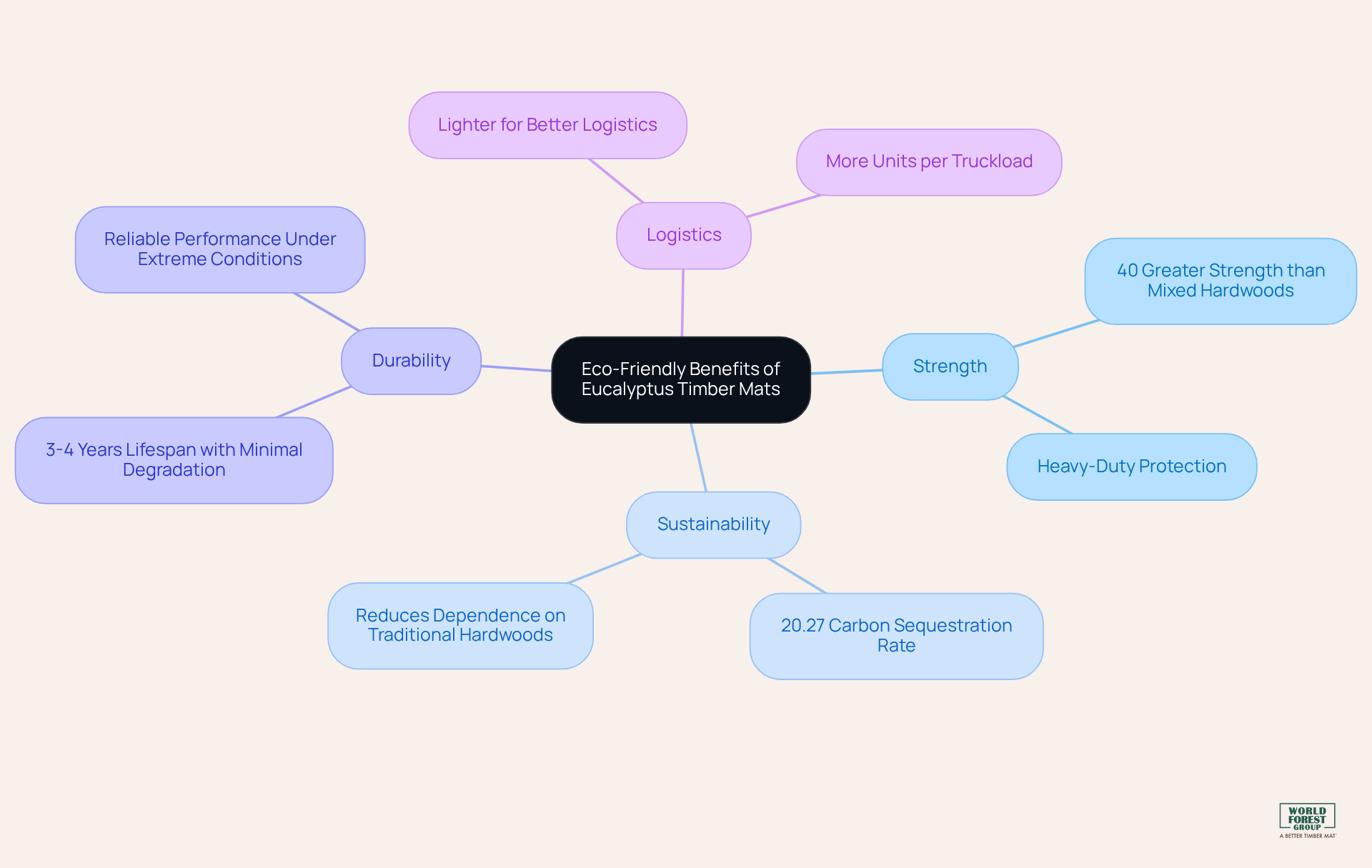

Eco-Friendly Benefits of Eucalyptus Timber Mats in Construction

Timber mats derived from Eucalyptus trees stand out not only for their exceptional strength but also for their environmentally friendly attributes. Sourced from rapidly expanding plantations, these products play a crucial role in sustainability by reducing dependence on traditional hardwoods. The production process is meticulously crafted to minimize environmental impact, establishing them as a responsible choice for companies committed to sustainable practices.

Notably, timber mats made from Eucalyptus trees exhibit a strength that is 40% greater than that of mixed hardwoods, providing heavy-duty protection at a competitive cost. Many Right of Way (ROW) companies report a lifespan of 3-4 years with minimal or no degradation, underscoring their durability. This superior strength translates into enhanced performance, improved safety, and a longer lifespan—elements that are vital for utility contractors.

Additionally, these mats are lighter, allowing for more units per truck, thereby optimizing logistics and operational efficiency. Trees of the genus, renowned for their impressive growth rates—some varieties can reach heights of up to 16 feet annually—also serve as significant carbon absorbers, with plantations achieving a carbon sequestration rate of 20.27%, far exceeding the 8% rate associated with mixed moist deciduous forests.

By opting for plant-based mats, companies can foster a safer and more efficient work environment while benefiting from a reduced total cost of ownership. This dual advantage of strength and sustainability positions heavy-duty access mats for boggy terrain as the optimal solution for construction projects aiming to enhance operational efficiency while contributing positively to the environment.

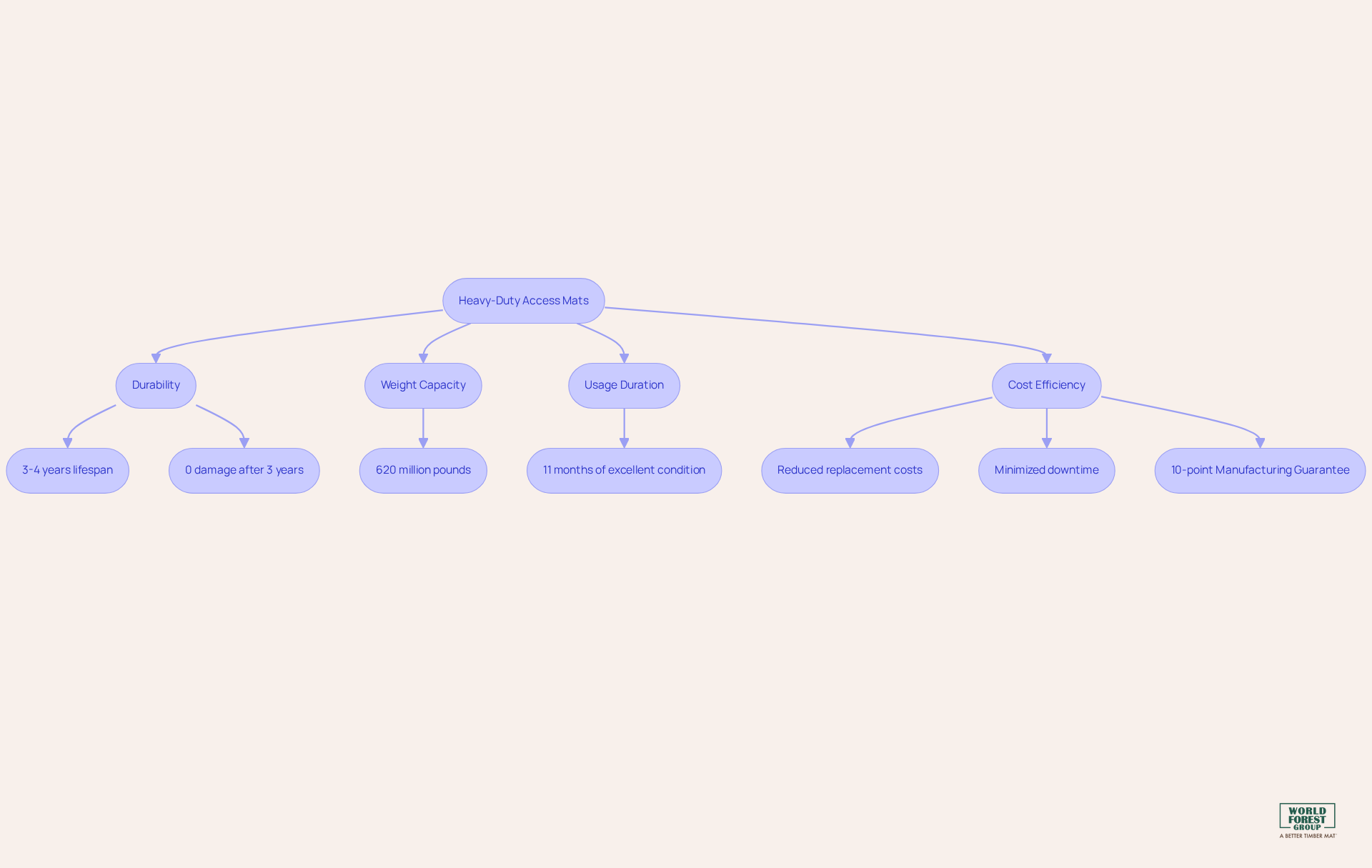

Long-Lasting Performance of Heavy-Duty Access Mats in Challenging Conditions

Heavy-duty access panels crafted from hardwood are renowned for their exceptional longevity, often lasting between three to four years with minimal deterioration. This durability is vital for construction projects operating under challenging conditions, where heavy-duty access mats for boggy terrain provide reliable solutions.

A project executive noted, “After approximately 620 million pounds and around 9,100 round trips, our flooring products remained in excellent condition after 11 months of use,” highlighting their ability to withstand significant weights and demanding environments.

Additionally, another company reported that after three years of usage, their 1,000 mats, made from a specific type of tree, exhibited no signs of damage, significantly reducing replacement costs and minimizing downtime.

This remarkable performance not only enhances operational efficiency but also positions heavy-duty access mats for boggy terrain as a prudent investment for construction firms aiming to optimize their resources and maintain safety standards.

Furthermore, all products are backed by a 10-point Manufacturing Guarantee, ensuring consistent quality and reliability, which significantly contributes to user satisfaction.

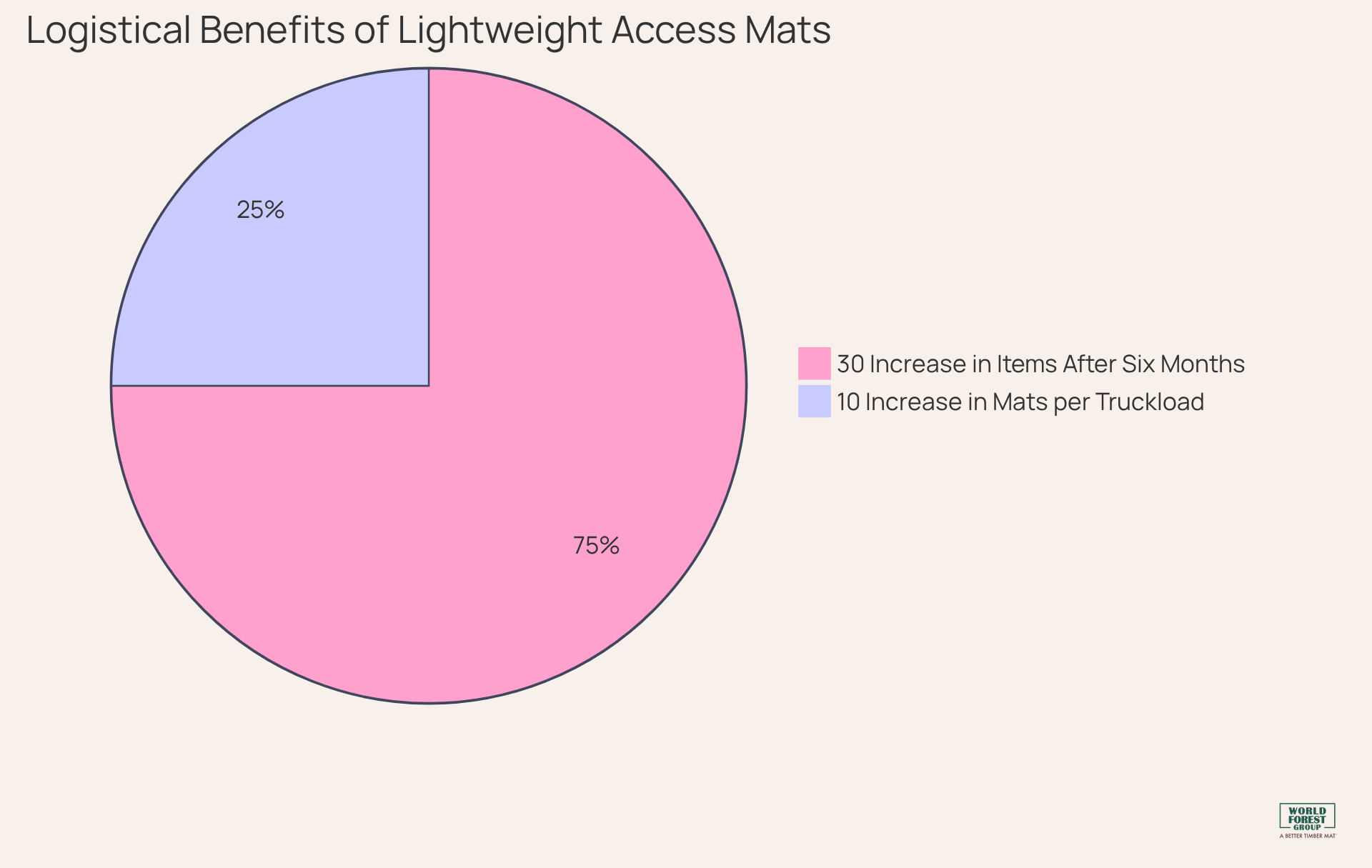

Lightweight Design of Access Mats: Improving Transport and Handling

Access panels are distinguished by their lightweight structure, significantly enhancing handling and transportation effectiveness on construction sites. This attribute is particularly beneficial in environments where logistics can present challenges.

The ability to accommodate approximately 10% more mats per truckload, and up to 30% additional items after six months, not only reduces transportation costs but also optimizes the overall logistics process. Furthermore, the decreased weight allows employees to manage the mats with greater ease, accelerating the setup procedure and minimizing idle time.

As a result, companies can achieve substantial reductions in transportation expenses while boosting operational efficiency, positioning these mats as a prudent investment for construction projects. Additionally, a Total Cost of Ownership analysis indicates that opting for these products can lead to significant long-term savings, underscoring their value in modern construction.

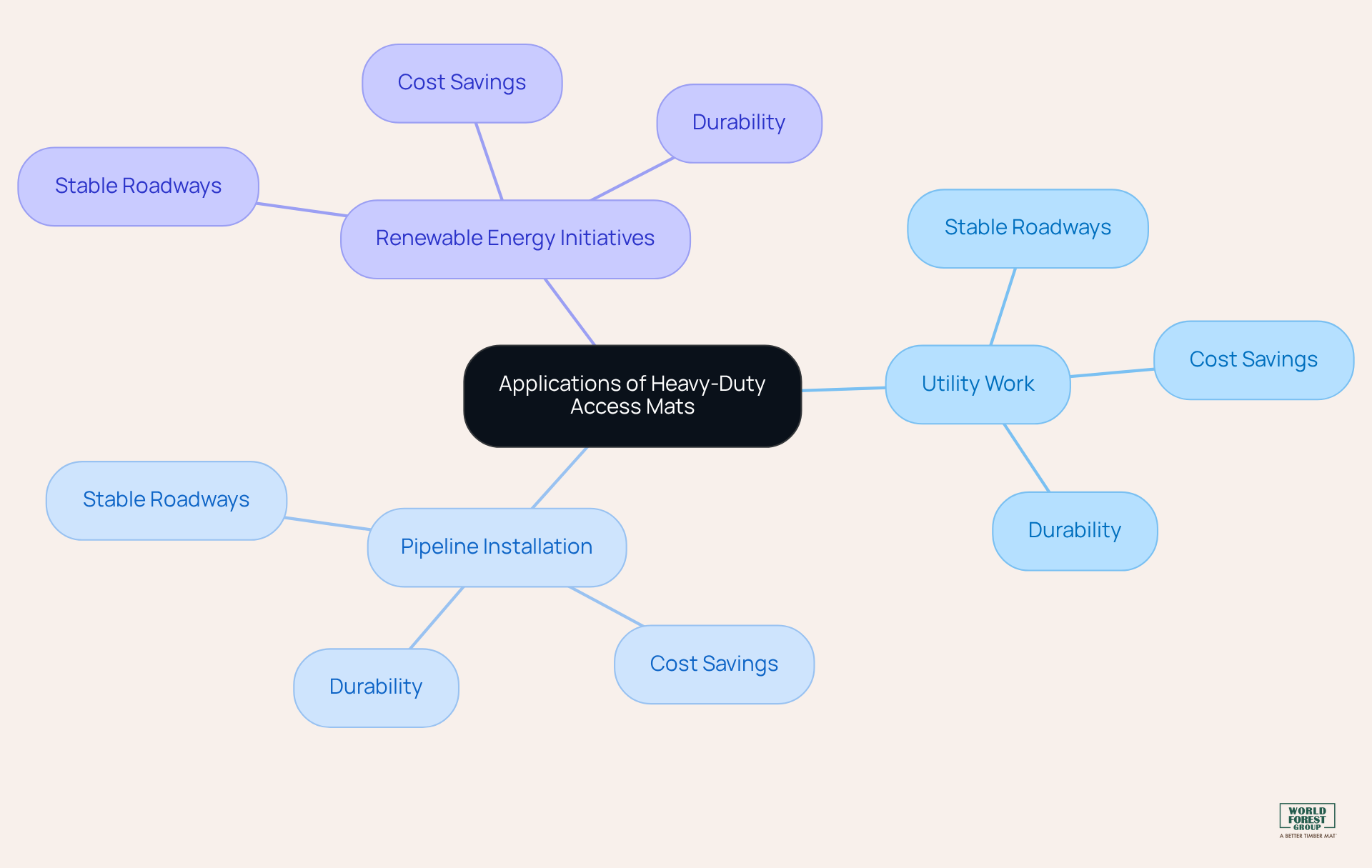

Versatile Applications of Heavy-Duty Access Mats in Construction Projects

Heavy-duty access panels are exceptionally versatile, catering to a diverse array of construction projects, such as utility work, pipeline installation, and renewable energy initiatives. Their ability to create stable temporary roadways over soft or uneven terrain with heavy-duty access mats for boggy terrain is crucial for contractors operating in various environments. Notably, certain types of foliage are acknowledged for their strength and durability, providing reliable options for both heavy equipment access and pedestrian pathways.

Many contractors have reported that heavy-duty access mats for boggy terrain can withstand significant weights while minimizing soil disruption, making them ideal for sensitive areas. Testimonials from industry professionals highlight the effectiveness of Eucalyptus mats in utility tasks, with one senior executive noting that these mats can save tens of thousands of dollars on each project. Another inventory supervisor praised the flooring’s integrity, asserting that flipping them is the best way to evaluate their durability.

With the global access platform market projected to reach $1.86 billion by 2025, and rental services potentially capturing 30% of the market, the demand for such innovative solutions continues to grow, driven by ongoing infrastructure projects and the need for sustainable practices. Moreover, these mats are reported to last 3-4 years with minimal to no deterioration, enhancing their reliability and effectiveness in challenging environments. This combination of cost savings and operational security positions these products as a preferred choice in the industry.

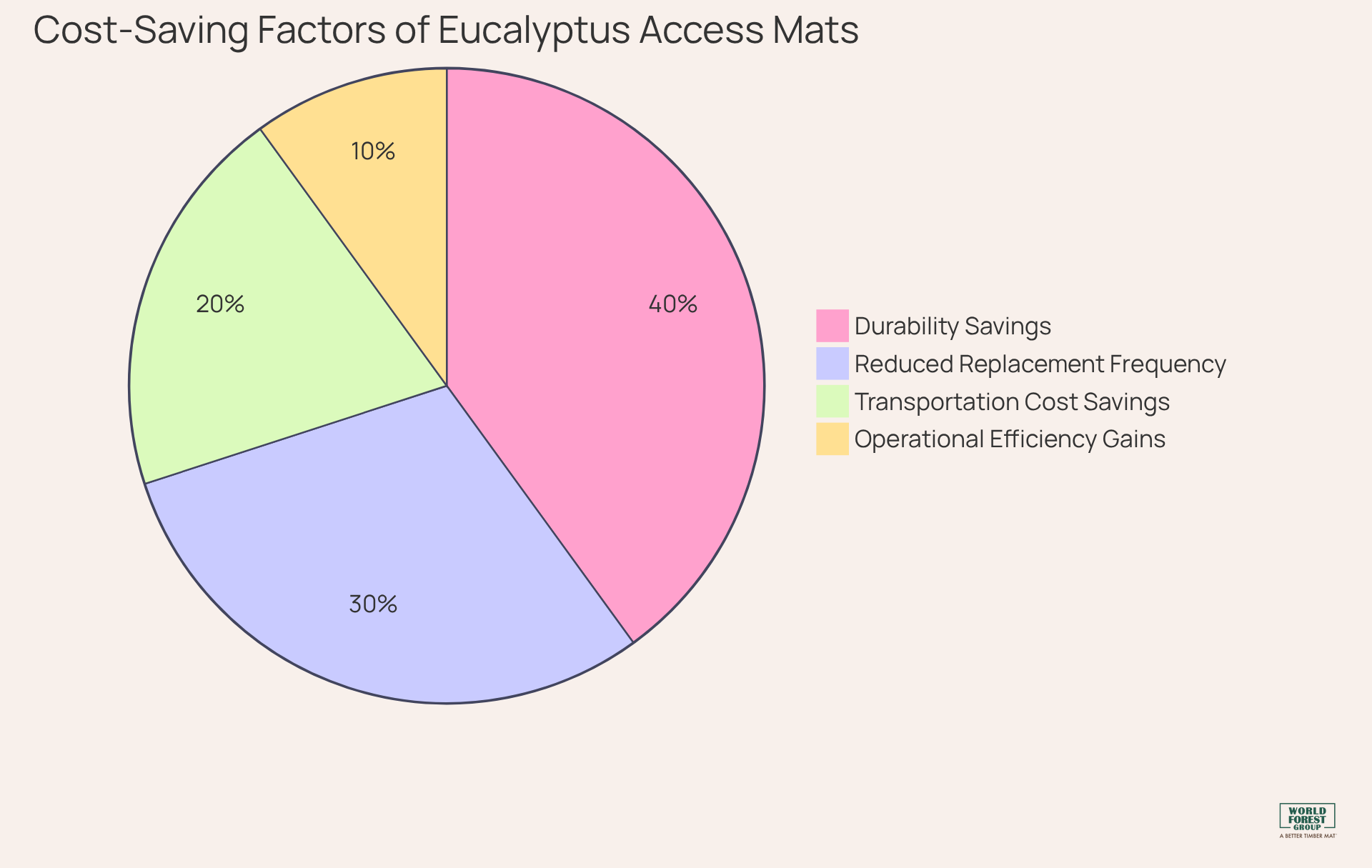

Cost-Effectiveness of Heavy-Duty Access Mats for Construction Efficiency

Investing in heavy-duty access mats made from Eucalyptus presents substantial financial advantages for construction firms. A recent case study illustrates that these mats are specifically engineered to handle heavy loads, with the E7M version tested under extreme conditions, including 92,000 lb. concrete trucks. This rigorous evaluation showcased exceptional durability, significantly lowering the frequency of replacements. Users frequently report a lifespan of 3-4 years with minimal loss, resulting in reduced long-term costs.

Furthermore, the introduction of slimmer mats (4″ and 5″) has further decreased expenses, making them a more cost-effective option compared to conventional alternatives. Their lightweight design not only facilitates easier handling but also minimizes transportation costs, allowing for more units per truckload. Moreover, the use of heavy-duty access mats for boggy terrain excels at reducing ground damage and preventing equipment delays, which can be costly in terms of project timelines and operational efficiency.

By utilizing heavy-duty access mats for boggy terrain, companies can circumvent the financial burden associated with frequent mat replacements and maintenance. Eucalyptus mats represent a strategic investment for contractors focused on optimizing their bottom line. Embrace the opportunity to enhance your operational efficiency and reduce costs—choose Eucalyptus mats for your next project.

Conclusion

Heavy-duty access mats for boggy terrain are an indispensable asset for construction projects, especially in challenging environments. Their remarkable strength, durability, and safety features render them a dependable choice for contractors aiming to boost operational efficiency while mitigating risks associated with unstable ground conditions.

This article underscores several key advantages of these mats, including:

- Their exceptional performance in marshy areas

- Enhanced safety features that minimize slip hazards

- Eco-friendly attributes that promote sustainability

Eucalyptus timber mats, in particular, are distinguished by their long-lasting durability and lightweight design, facilitating easier transport and handling. Furthermore, the cost-effectiveness of these mats is evident through reduced replacement frequency and lower total ownership costs, making them a prudent investment for construction firms.

Ultimately, adopting heavy-duty access mats not only enhances safety and efficiency on construction sites but also fosters sustainable practices within the industry. By choosing these innovative solutions, companies can ensure their projects proceed seamlessly, lower operational costs, and positively contribute to environmental stewardship. Investing in heavy-duty access mats is not merely a choice; it is a commitment to excellence in construction and safety.

Frequently Asked Questions

What are the key benefits of World Forest Group’s Eucalyptus timber mats?

World Forest Group’s Eucalyptus timber mats provide exceptional strength, outperforming oak by 40% and exhibiting up to 300% greater durability than various mixed hardwoods. They are particularly effective in boggy terrain, where traditional mats often struggle.

How do Eucalyptus timber mats compare to Southern Red Oak?

Eucalyptus timber mats show a 23% increase in shear strength, a 43% enhancement in bending strength, and a 20% reduction in weight compared to Southern Red Oak.

What load capacity can Eucalyptus timber mats handle?

These mats have been tested with loaded concrete vehicles weighing up to 92,000 lbs, ensuring they can withstand substantial loads safely and reliably.

What is the lifespan of Eucalyptus timber mats?

The lifespan of these timber mats is 3-4 years, with minimal to no decline in quality over time.

How do Eucalyptus timber mats contribute to cost savings?

They offer a total cost of ownership that is 10-40% lower than alternative options, making them a cost-effective choice for contractors.

What safety features do heavy-duty access mats provide?

Heavy-duty access mats feature slip-resistant mats that enhance traction for vehicles and pedestrians, significantly reducing the likelihood of accidents in wet conditions.

Why are heavy-duty access mats important for construction sites?

They help sustain a safe working environment by alleviating risks associated with slips, trips, and falls, which are among the leading causes of workplace injuries.

What guarantee does World Forest Group provide for their products?

World Forest Group offers a 10-point Manufacturing Guarantee, ensuring consistent quality and reliability of their heavy-duty access mats.

How can companies benefit from investing in heavy-duty access mats?

By investing in these mats, companies can enhance operational safety and efficiency, allowing workers to perform their duties without the persistent worry of slipping or falling.