Key Highlights:

- Eucalyptus mats are designed for heavy-duty applications, offering strength ratings 40% higher than oak and up to 300% higher than various hardwoods.

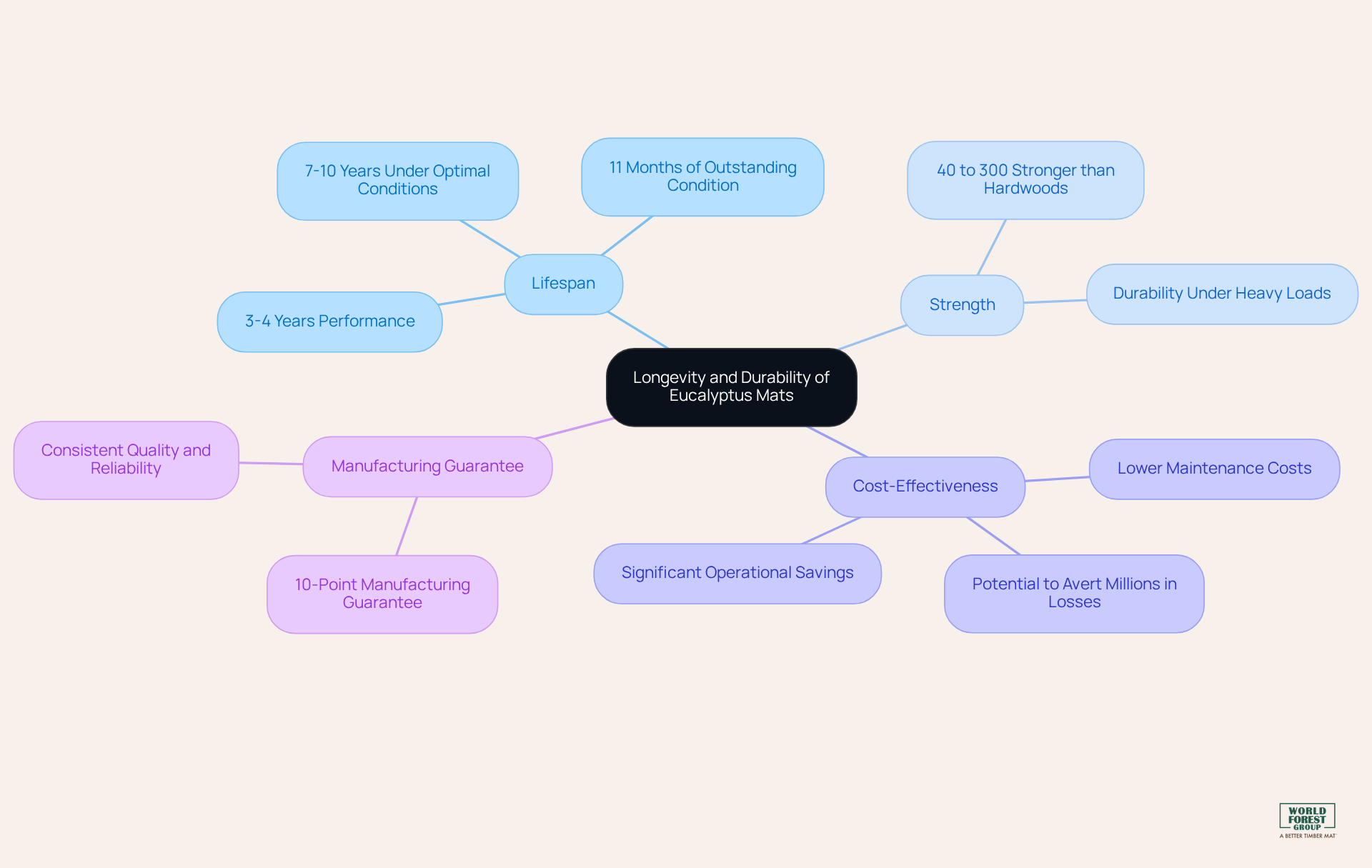

- These mats have a lifespan of 3-4 years with minimal deterioration, enhancing reliability in construction settings.

- They are 20% lighter than Southern Red Oak, improving handling and transport efficiency.

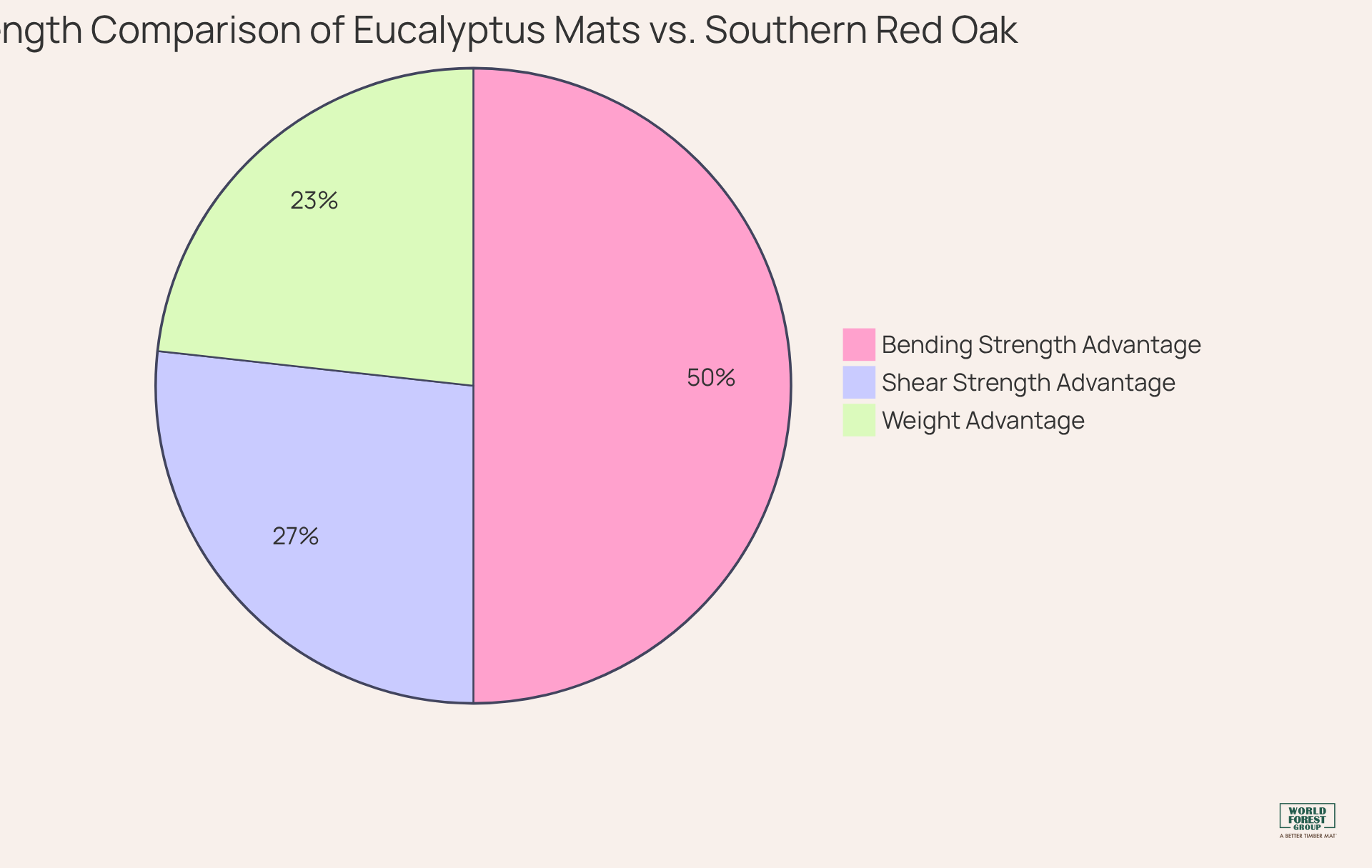

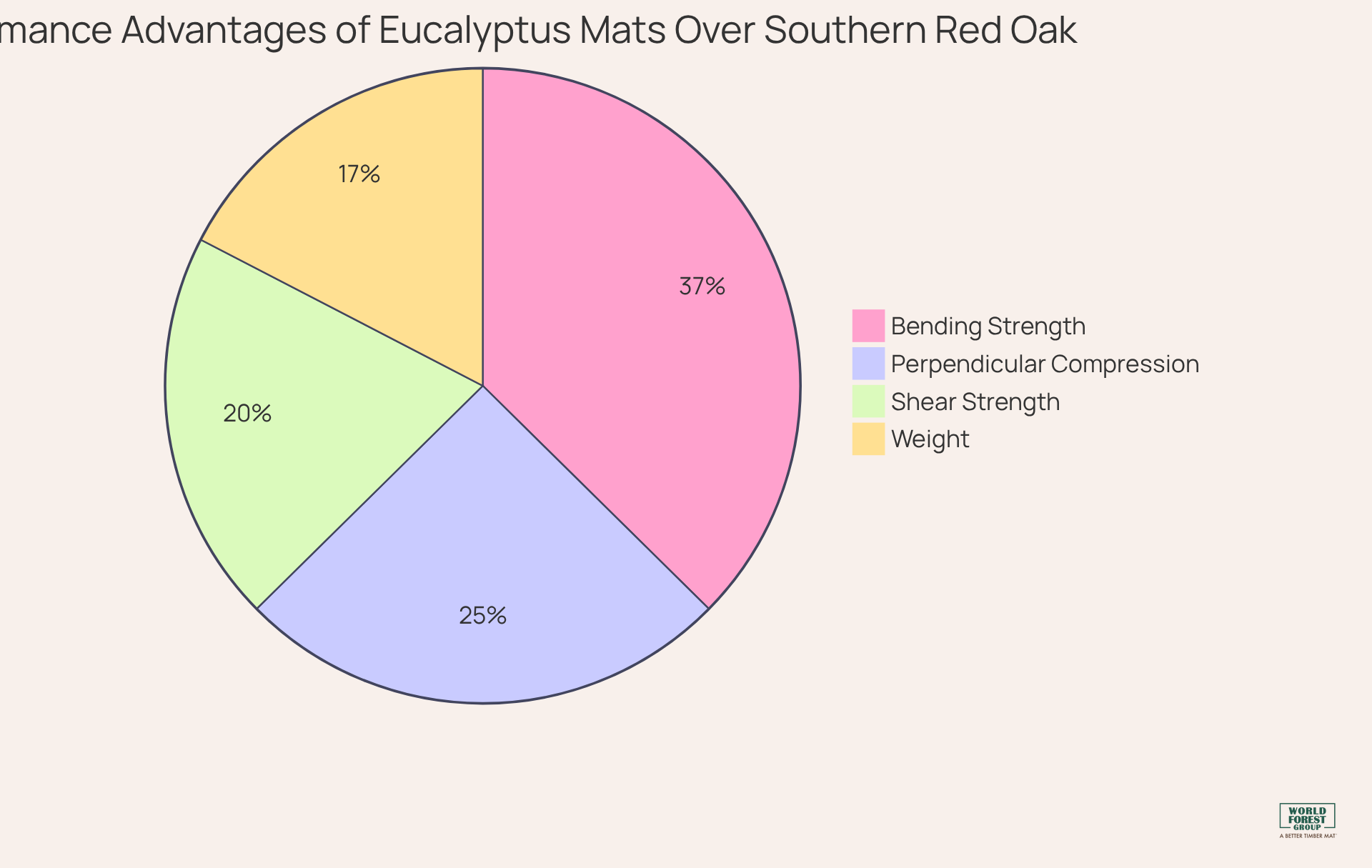

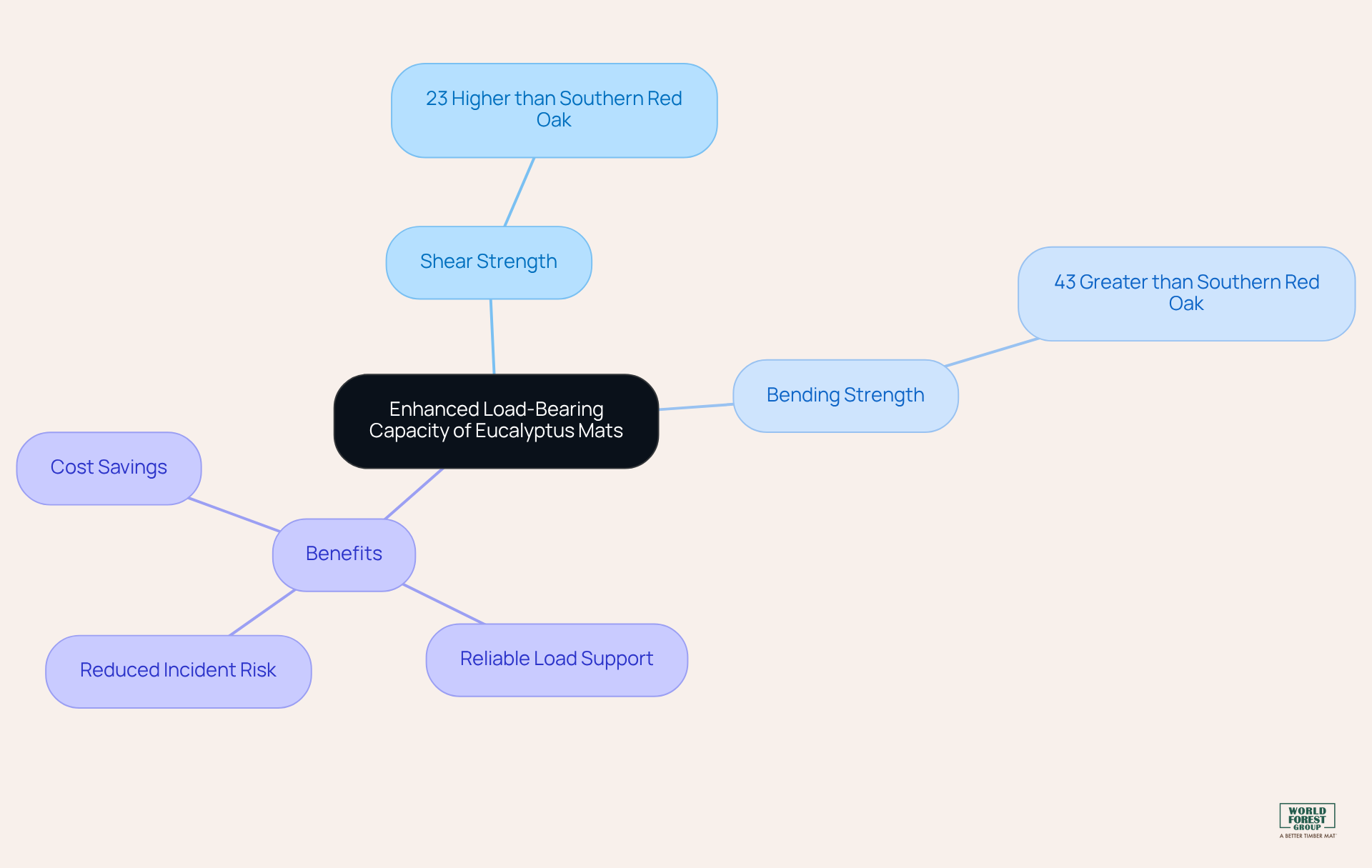

- Eucalyptus mats provide 23% higher shear strength, 43% greater bending strength, and 29% increased perpendicular compression compared to Southern Red Oak.

- The mats are sourced from sustainably managed woodlands, making them an eco-friendly choice for construction.

- Lightweight design leads to reduced shipping costs and lower carbon footprint, with reported savings of 12-15% in transport expenses.

- Each mat is backed by a 10-point Manufacturing Guarantee, ensuring consistent quality and reliability.

- Positive client testimonials highlight significant cost savings and exceptional performance in demanding conditions.

- Eucalyptus mats are versatile, suitable for various construction applications, including temporary roadways and work mats.

- World Forest Group emphasises customer satisfaction and support, enhancing client loyalty and trust.

Introduction

Custom-built eucalyptus mats are revolutionizing the construction landscape, providing an exceptional blend of strength, sustainability, and cost-effectiveness. Their impressive load-bearing capabilities surpass those of traditional hardwoods, enhancing operational efficiency while promoting eco-friendly practices within the industry.

As organizations tackle the complexities of large-scale projects, a critical question emerges: what specific advantages do these innovative mats offer, and in what ways can they redefine safety and performance standards on job sites?

World Forest Group Eucalyptus Mats: Superior Strength for Heavy-Duty Applications

World Forest Group’s custom-built eucalyptus mats for large projects are meticulously designed using Eucalyptus tree fibers to deliver exceptional strength, making them the preferred choice for demanding applications. Their strength rating exceeds that of oak by 40% and surpasses various hardwoods by up to 300%, ensuring they can endure heavy loads and rigorous conditions. This remarkable strength not only bolsters safety on job sites but also significantly mitigates the risk of mat failure during critical operations.

Numerous firms report that these mats possess an extended lifespan, with usage lasting 3-4 years and exhibiting negligible deterioration, thereby enhancing their reliability in vital settings. Additionally, users can fit 30% more items per truckload after six months, optimizing transport efficiency. When compared to Southern Red Oak, Eucalyptus products demonstrate:

- 23% higher shear strength

- 43% greater bending strength

- 20% lighter, facilitating ease of management and transport

Each mat is backed by a 10-point Manufacturing Guarantee, empowering clients to operate with heightened confidence, knowing they are supported by products that meet the stringent demands of modern construction. Testimonials from industry leaders underscore the cost savings and exceptional performance of custom-built eucalyptus mats for large projects, reinforcing their value as a sustainable and economical solution for the construction and heavy industries.

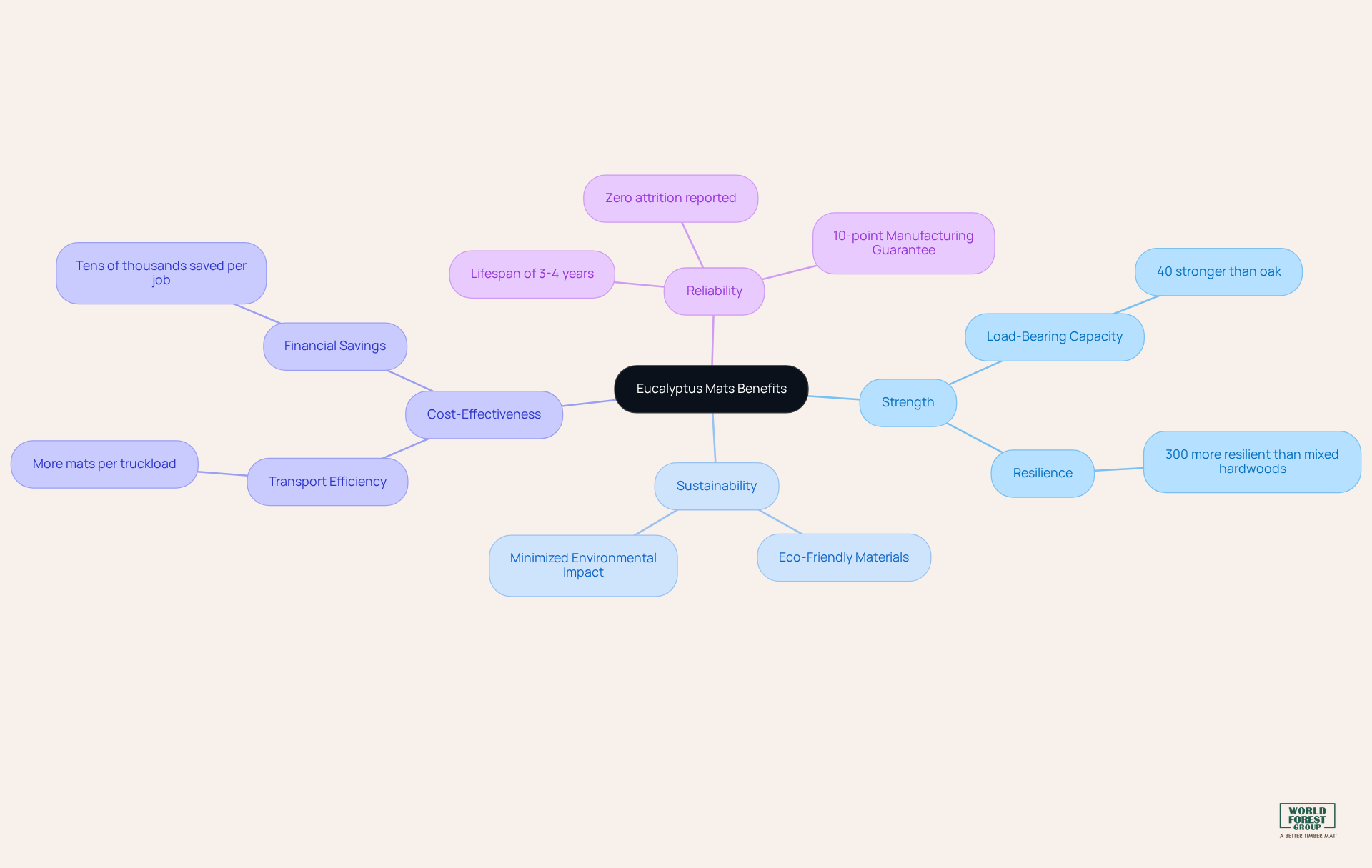

Eco-Friendly Construction: The Sustainability Benefits of Eucalyptus Mats

These mats stand out due to their exceptional durability and environmentally friendly characteristics. Sourced from sustainably managed woodlands, they play a crucial role in fostering responsible forestry practices. Notably, when compared to Southern Red Oak, these mats offer:

- 23% higher shear strength

- 43% enhanced bending strength

- 29% increased perpendicular compression

- 20% lighter weight

This makes custom-built eucalyptus mats for large projects an optimal choice for construction projects.

The production of tree-based textiles requires significantly less energy and fewer resources compared to traditional hardwood options, establishing them as a more sustainable alternative. By choosing custom-built eucalyptus mats for large projects, organizations can bolster their sustainability initiatives while ensuring superior performance and longevity. With a lifespan of 3-4 years and minimal loss reported by numerous ROW companies, custom-built eucalyptus mats for large projects deliver a practical solution that meets the demands of modern eco-conscious construction.

Furthermore, this type of timber exhibits a remarkable durability, lasting over 50 years without substantial decay. The 10-point Manufacturing Guarantee provided by World Forest Group assures consistent quality and reliability, making these products a prudent investment for utility contractors. Their lighter weight facilitates easier handling and transportation, thus enhancing operational efficiency while reducing the total cost of ownership.

Transport Efficiency: Lightweight Design of Eucalyptus Mats Reduces Costs

Lightweight sheets stand out due to their innovative design, which significantly enhances handling and transport efficiency. This capability enables companies in the building sector to maximize truckload capacity, allowing for the simultaneous transportation of additional materials. Consequently, shipping costs are notably reduced, leading to considerable project savings.

Moreover, the transport efficiency achieved not only results in financial advantages but also contributes to a lower carbon footprint associated with logistics. Businesses utilizing tree-based mats, for instance, have reported a 12-15% reduction in shipping expenses compared to traditional hardwood alternatives.

The E7M mat, engineered specifically for heavy loads, has been rigorously tested with loaded concrete trucks weighing up to 92,000 lbs, showcasing exceptional durability and performance. This combination of cost savings, enhanced durability, and ecological responsibility positions custom-built eucalyptus mats for large projects as ideal solutions, underscoring their value in the construction industry while supporting World Forest Group’s commitment to carbon-neutral initiatives.

Longevity and Durability: Eucalyptus Mats Outlast Traditional Options

Specialized mats are engineered for exceptional durability, often surpassing the lifespan of traditional hardwood alternatives. Users consistently report that these products maintain performance for 3-4 years, significantly reducing the need for replacements. A project executive from a leading EPC contractor noted that after 11 months of use, their wooden mats remained in outstanding condition, enduring approximately 620 million pounds and 9,100 round trips. This remarkable durability, coupled with the fact that these products are 40% to 300% stronger than conventional hardwoods, leads to lower maintenance costs over time, establishing them as a cost-effective choice for businesses aiming to optimize their investment in building materials. Additionally, all timber sheets are backed by a 10-point Manufacturing Guarantee, ensuring consistent quality and reliability. Clients have reported that choosing these mats can avert millions in losses, further underscoring their significance in fostering a safer and more efficient workplace.

Safety First: Enhanced Load-Bearing Capacity of Eucalyptus Mats

Safety is paramount in construction, and these mats excel with their superior load-bearing capacity. Compared to Southern Red Oak, these fibers exhibit:

- 23% higher shear strength

- 43% greater bending strength

This makes them exceptionally reliable for supporting heavy loads without compromising structural integrity. Designed to create a stable foundation for both equipment and personnel, these mats significantly reduce the risk of incidents, adhering to safety standards that mandate robust ground protection.

Notably, construction sites utilizing specialized coverings have reported lower accident rates than those using traditional hardwood alternatives, underscoring their effectiveness in enhancing site safety. A senior project executive from a nationwide EPC highlighted the remarkable cost savings and efficiency of these mats, further affirming their critical role in maintaining high safety standards at construction sites.

Versatile Applications: Eucalyptus Mats for Diverse Construction Needs

Eucalyptus panels stand out for their remarkable adaptability, making them ideal for a wide range of building applications. They serve effectively as temporary roadways and work mats, providing robust support for heavy machinery. Their exceptional strength—40% more robust than oak and up to 300% stronger than various mixed hardwoods—ensures that utility contractors, pipeline firms, and civil engineering companies can rely on them to meet the rigorous demands of any job site.

With a lifespan of 3-4 years noted by numerous users, these products not only enhance operational efficiency but also lead to substantial cost savings by minimizing the need for frequent replacements. The increasing market demand for timber products in the utility and pipeline industries underscores their significance in modern construction methods, where durability and flexibility are paramount.

Testimonials from utility contractors highlight the effectiveness of custom-built eucalyptus mats for large projects in challenging conditions, reinforcing their value as a prudent investment.

Customer-Centric Service: World Forest Group’s Commitment to Client Satisfaction

World Forest Group excels in its customer-centric approach, ensuring clients receive unwavering support throughout their projects. From initial inquiries to post-purchase assistance, the organization is committed to delivering exceptional service. This commitment to customer satisfaction is reflected in the quality of their timber products, which are not only 40% more robust than oak and up to 300% more resilient than various mixed hardwoods but also come with a 10-point Manufacturing Guarantee. Clients can confidently trust that they are receiving a reliable product every time, significantly enhancing their overall experience.

Moreover, the organization’s focus on sustainability and ethical practices fosters loyalty among clients, positioning World Forest Group as a preferred partner in heavy civil engineering and renewable energy applications. Favorable reviews from clients underscore the cost-efficiency and outstanding performance of custom-built eucalyptus mats for large projects, further solidifying the organization’s reputation as a leader in the construction supply industry. With a proven track record, World Forest Group invites you to experience the difference in quality and service that sets them apart.

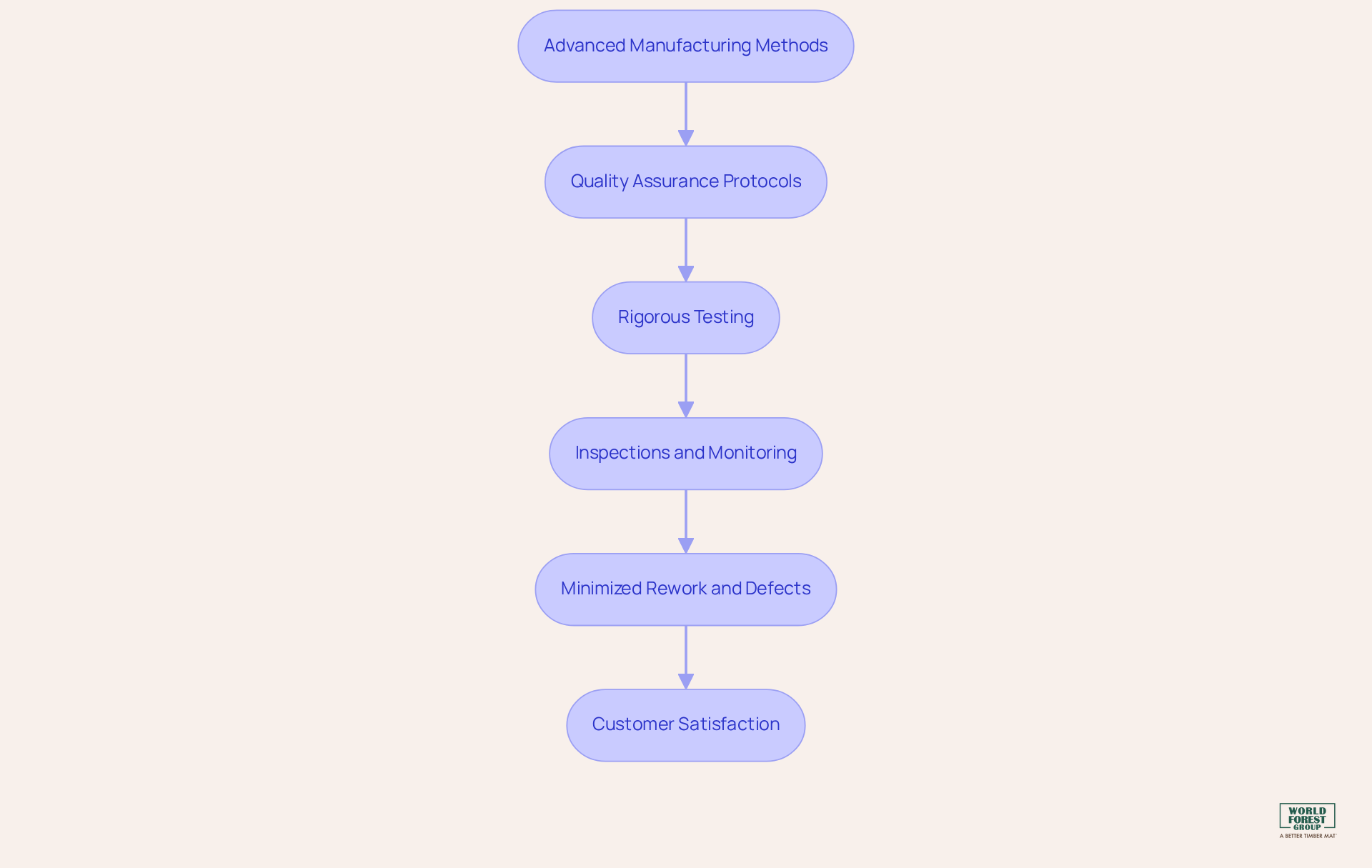

Innovative Manufacturing: Quality Assurance in Eucalyptus Mat Production

World Forest Group employs advanced manufacturing methods to uphold the highest standards in mat production. Each mat undergoes rigorous testing and quality assurance protocols, including strict adherence to ASTM standards, and is backed by a 10-point Manufacturing Guarantee. This unwavering commitment to quality not only guarantees that customers receive reliable products that meet stringent performance criteria but also reinforces the company’s reputation as a trusted supplier in the matting industry.

For instance, the implementation of robust quality assurance measures—such as thorough inspections and continuous monitoring of production processes—minimizes rework and defects, ultimately enhancing customer satisfaction and cost savings. Client testimonials further validate the exceptional performance of the products crafted from a specific tree under extreme conditions, with many reporting zero attrition after prolonged use.

Significantly, these mats are 40% stronger than oak and up to 300% stronger than various mixed hardwoods, making them an outstanding choice for demanding applications. Additionally, their lighter weight and lower total cost of ownership compared to Southern Red Oak further enhance their appeal, ensuring clients benefit from both performance and efficiency.

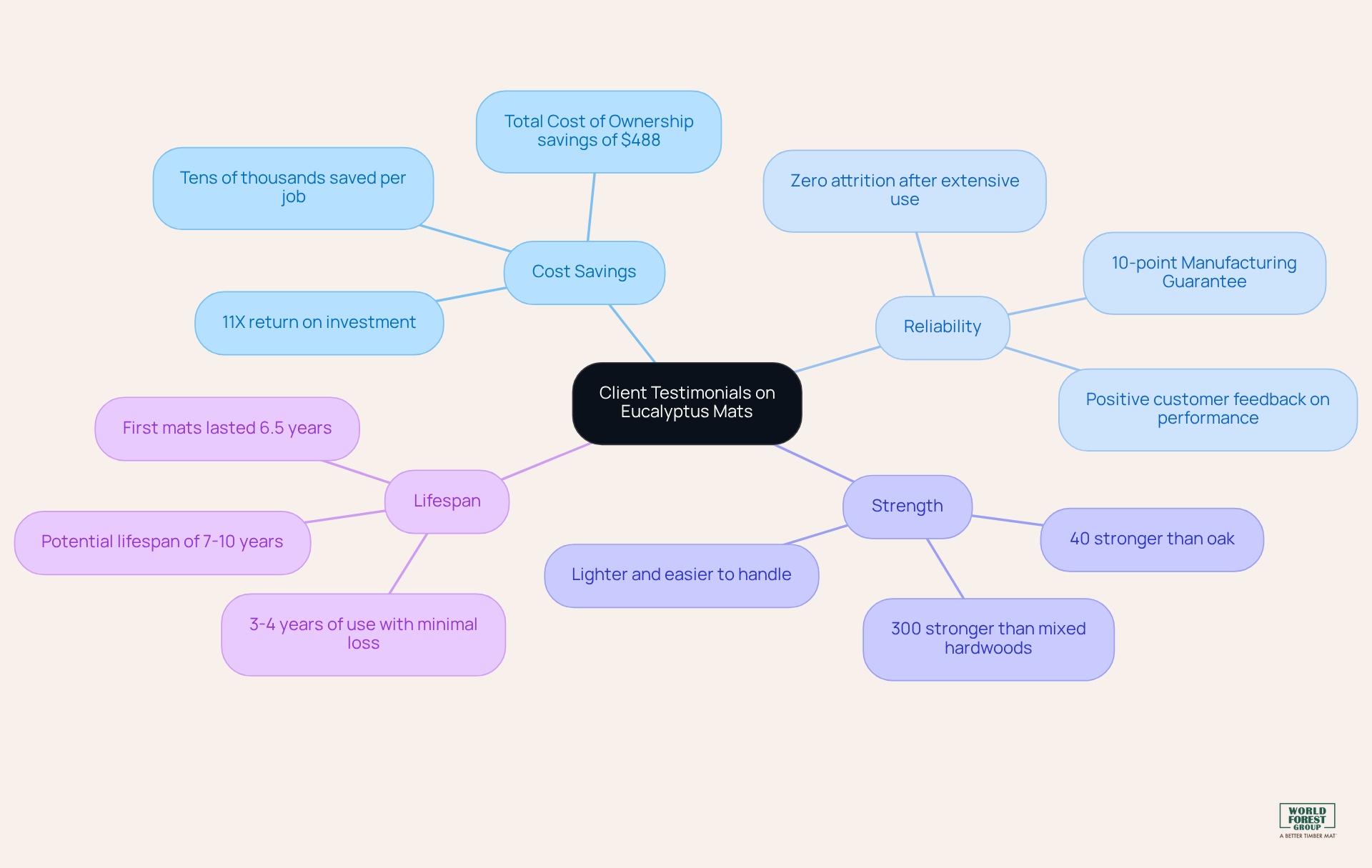

Proven Performance: Client Testimonials on Eucalyptus Mats

Numerous client reviews affirm the proven effectiveness of these mats in challenging conditions. A senior executive from a leading flooring wholesaler stated, “We anticipate this product to save us tens of thousands of dollars per job,” underscoring the cost-efficiency of these mats. Users consistently report zero attrition after extensive use, demonstrating the products’ reliability and effectiveness. Such positive experiences reinforce the value of these products as a prudent investment for organizations seeking to enhance their operational efficiency and safety protocols.

Furthermore, with these mats being up to 300% stronger than various mixed hardwoods and backed by a 10-point Manufacturing Guarantee, clients can depend on their consistent quality and durability. Many companies also report a lifespan of 3-4 years with minimal loss, translating to substantial cost savings over time. The Total Cost of Ownership analysis indicates that opting for these types of mats can yield significant long-term savings.

For utility contractors considering specialized mats, evaluating their specific project requirements and potential long-term benefits could lead to improved operational outcomes.

Game-Changing Benefits: Why Eucalyptus Mats Are Essential for Large Projects

Custom-built eucalyptus mats for large projects are revolutionizing the industry by offering an exceptional blend of strength, sustainability, and affordability. With a load-bearing capacity that surpasses oak by 40% and demonstrates up to 300% greater resilience than many mixed hardwoods, these mats are engineered to withstand heavy weights while remaining lightweight for easier maneuvering and transport. Users frequently report a lifespan of 3-4 years with minimal degradation, significantly decreasing the necessity for frequent replacements. For instance, a senior manager from a nationwide ROW firm reported zero attrition after three years of utilizing these mats, underscoring their reliability in demanding conditions.

The cost-effectiveness of Eucalyptus products is further highlighted by their ability to enhance operational efficiency across various sectors. The E7M Access Platform, for example, is designed for heavy-duty protection at a competitive price, allowing contractors to transport significantly more mats per truckload compared to traditional options, thereby boosting transport efficiency. This not only minimizes logistics costs but also mitigates environmental impacts, aligning with the growing demand for eco-friendly building materials. A senior project executive noted that these mats are projected to save tens of thousands of dollars per job, illustrating their financial advantages.

In addition to their robust performance, these products are backed by a 10-point Manufacturing Guarantee, ensuring consistent quality and reliability for utility contractors, pipeline companies, and construction firms. Client testimonials consistently praise their exceptional performance in challenging conditions, with many asserting that the products endure remarkably well against heavy loads and harsh environments. This dependability is vital for upholding safety standards and reducing costs linked to mat replacement and maintenance, establishing custom-built eucalyptus mats for large projects as an indispensable choice for contemporary construction.

Conclusion

Custom-built eucalyptus mats are revolutionizing large construction projects by merging exceptional strength, sustainability, and cost-effectiveness. Their superior performance compared to traditional hardwoods, such as Southern Red Oak, is evident, boasting a 40% greater load-bearing capacity and up to 300% increased resilience. This makes them an indispensable solution for demanding applications. With a lifespan of 3-4 years and minimal degradation, these mats not only enhance operational efficiency but also significantly lower replacement costs, ensuring a reliable investment for any construction endeavor.

Key benefits include:

- Eco-friendly production, which utilizes fewer resources than traditional materials.

- A lightweight design that optimizes transport efficiency.

- Companies employing eucalyptus mats report substantial cost savings in logistics and project execution.

- Many clients experience zero attrition even after extensive use.

- The 10-point Manufacturing Guarantee from World Forest Group emphasizes a commitment to quality and reliability.

Ultimately, embracing custom-built eucalyptus mats is not merely a strategic choice for enhancing project performance; it represents a significant step towards sustainable construction practices. As the demand for eco-friendly materials continues to escalate, organizations are urged to consider the long-term benefits of eucalyptus mats in their projects, ensuring both operational success and environmental responsibility.

Frequently Asked Questions

What are World Forest Group’s eucalyptus mats made from?

World Forest Group’s eucalyptus mats are custom-built using Eucalyptus tree fibers, which provide exceptional strength for heavy-duty applications.

How does the strength of eucalyptus mats compare to other woods?

Eucalyptus mats have a strength rating that exceeds oak by 40% and various hardwoods by up to 300%. They also demonstrate 23% higher shear strength and 43% greater bending strength compared to Southern Red Oak.

What is the lifespan of eucalyptus mats?

Eucalyptus mats have an extended lifespan of 3-4 years with negligible deterioration, making them reliable for demanding applications.

How do eucalyptus mats enhance transport efficiency?

Eucalyptus mats are 20% lighter than Southern Red Oak, allowing users to fit 30% more items per truckload after six months, which optimizes transport efficiency and reduces shipping costs.

What guarantees come with eucalyptus mats?

Each mat is backed by a 10-point Manufacturing Guarantee, ensuring clients can operate with confidence knowing the products meet stringent construction demands.

How do eucalyptus mats contribute to sustainability?

Sourced from sustainably managed woodlands, eucalyptus mats require significantly less energy and fewer resources for production compared to traditional hardwood options, making them an eco-friendly choice.

What are the financial benefits of using eucalyptus mats?

Businesses using eucalyptus mats have reported a 12-15% reduction in shipping expenses compared to traditional hardwood alternatives, leading to considerable project savings.

How durable are eucalyptus mats in the long term?

Eucalyptus mats exhibit remarkable durability, lasting over 50 years without substantial decay, making them a prudent investment for utility contractors.

What feedback do industry leaders provide about eucalyptus mats?

Testimonials from industry leaders highlight cost savings and exceptional performance, reinforcing the value of custom-built eucalyptus mats in construction and heavy industries.