Summary

(Updated December 12, 2025)

- This article explores why Eucalyptus timber mats for ground protection are the simple solution: faster, better, and much less expensive over the long-term.

- Stronger results are a result of stronger materials. Stronger means longer-lasting, less replacements, safer operations.

- Every Eucalyptus timber mat is the same. So, you can rely on getting the same results all the time.

Overview

Eucalyptus timber mats stand out in ground protection because they do three things at once. They are a) stronger than traditional hardwoods, b) last longer in the field, and weigh less per mat. Those three advantages show up directly in reduced breakage, fewer replacements, and lower trucking and handling costs. In practice, well‑made Eucalyptus timber mats routinely deliver 5–7 years of service with minimal loss. Crews stay productive and asset managers see fewer surprises in the budget.

Why Eucalyptus Mats Change Things

Eucalyptus is a large genus—over 700 species. Some Eucalyptus plantation species are known for rapid growth and the ability to thrive where many other species do not. That fast growth, combined with the inherent strength of the wood, allows it to compete head‑to‑head with traditional hardwoods on performance. And, for construction and utility work, that means a lighter, stronger mat that behaves well under load. Plantation Eucalyptus is also more sustainable sourcing.

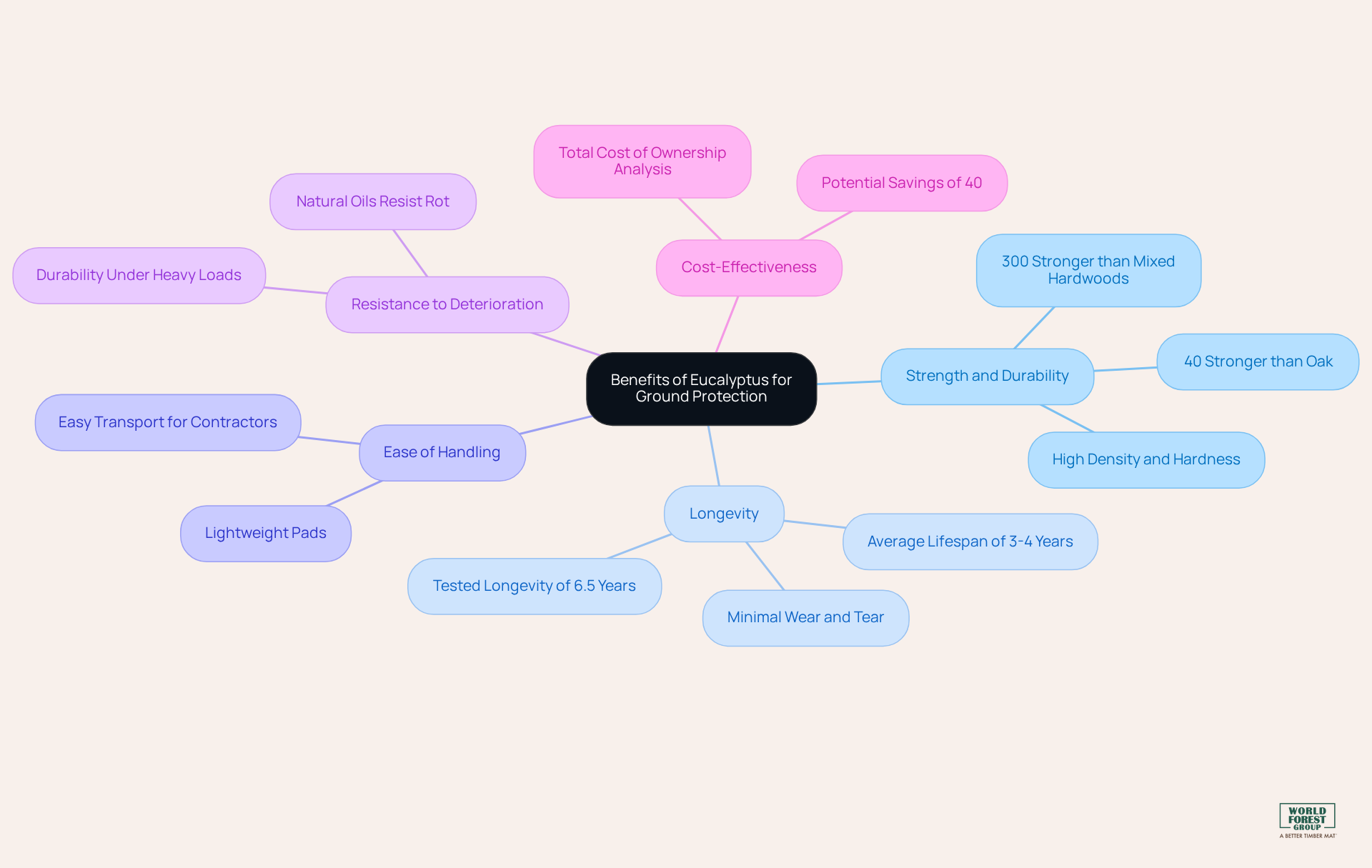

On the ground, Eucalyptus timber mats create a stable surface for cranes, drill rigs, and line trucks, reducing gouging, soil compaction, and cleanup costs. Field data and third‑party testing show that Eucalyptus can be roughly 40% stronger than oak and up to 200-300% stronger than common mixed hardwood. Failures are less frequent when conditions are at their worst.

Strength, Lifespan and Total Cost

Several characteristics drive the economics. First, Eucalyptus timber mats have an expected life of about 5–7 years in typical utility and construction use. Many fleets report minimal loss over that period. Second, their 20% lighter weight than comparable US species means more mats per truck. Lighter weight combined with standardized manufacturing means faster handling with the same equipment. That drives savings in mobilization, demobilization, and day‑to‑day moves.

Mechanical testing shows meaningful gains in shear and bending strength compared with almost any USA species. Contractors get more performance per pound. When you do the math on a Total Cost of Ownership basis (purchase price, freight, handling, expected life, and disposal) Eucalyptus mats can return many times their initial premium relative to low‑cost mixed hardwood options

Design, Guarantees, and Field Proof

The wood itself brings natural resistance to pests and decay, which reduces future mat purchases and clean up cost. A structured manufacturing program, backed by a 10‑point guarantee, helps ensure that each eucalyptus timber mat meets tight standards on species, moisture content, dimensions, and fasteners, so performance is repeatable from project to project.

Customer experience tracks closely with the lab data. Utility and EPC contractors report essentially zero attrition on large fleets over multi‑year runs. One factory reported roughly 620 million pounds and about 9,100 round trips over 11 months. The Eucalyptus mats remained in A-grade condition at the end, saving tens of thousands of dollars versus expected replacement rates.

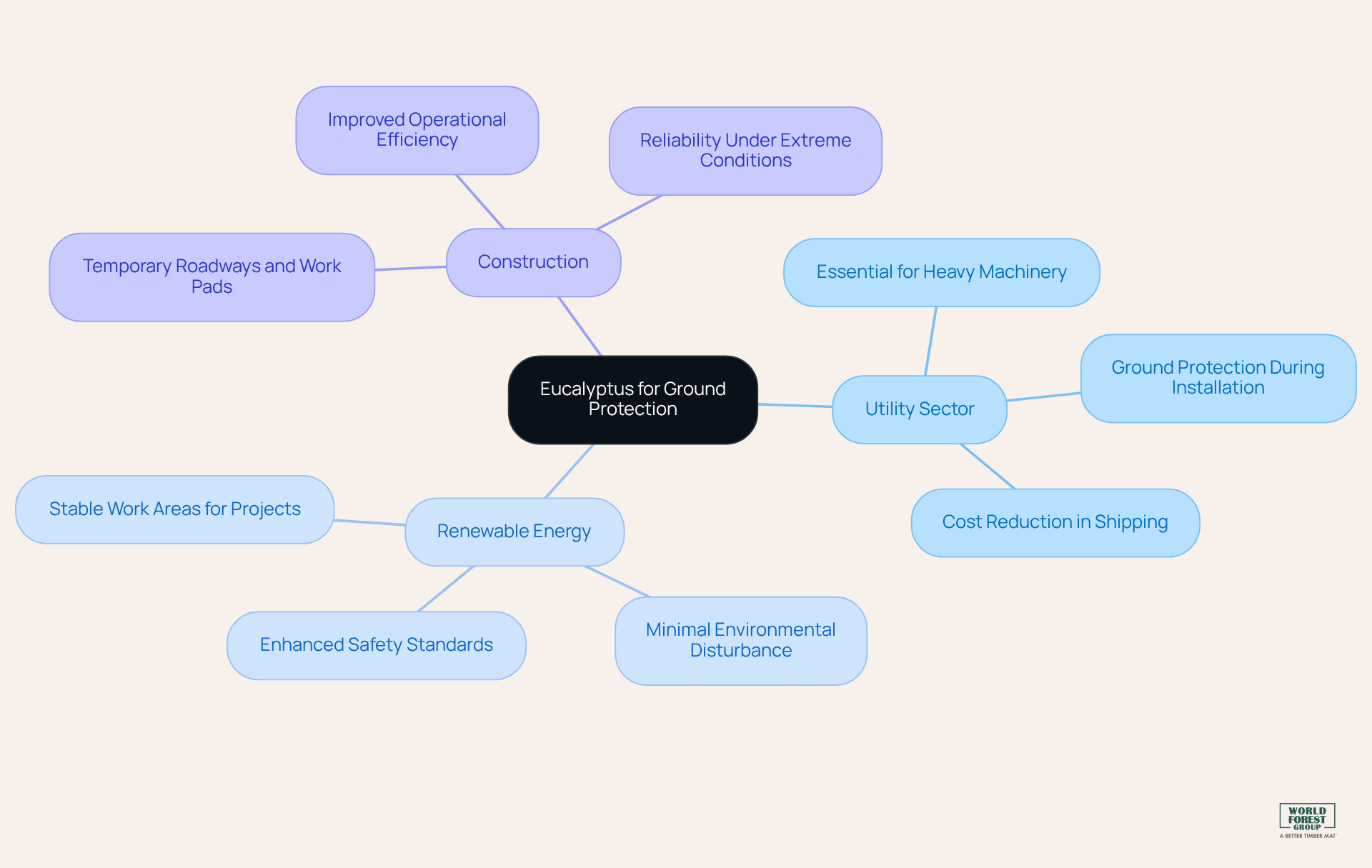

Practical Applications of Eucalyptus in Ground Protection

Eucalyptus timber mats show up wherever there is heavy equipment and soft or sensitive ground. Utilities use them under T‑line work and substation expansions. Pipeline projects use them to maintain access in wet conditions. Renewable developers rely on them to stabilize crane paths and turbine pads for wind, and to protect graded pads and access roads for solar.

General contractors deploy them as temporary roads, crane mats, and work platforms to keep schedules on track when weather and soil conditions do not cooperate. Because they are lighter, contractors can often load roughly 20% more mats per truck compared with many almost any hardwood fleet. That cuts freight and yard‑to‑site shuttles. Combined with longer life and stronger performance under load, that freight advantage makes Eucalyptus mats less a preferred reusable asset. The mats earn their keep year after year and as an essential product for any project.

Conclusion

Eucalyptus timber mats deserve to earn their place in your ground protection solutions. That’s because they deliver more strength, longer life, and better environmental performance than typical mixed hardwood options. For contractors and utilities, that combination turns mats from a consumable into a reusable asset that protects people, equipment, and budgets over many projects.

The core advantages are straightforward. Eucalyptus is significantly stronger than traditional hardwoods, yet lighter, so users see better performance and can move more mats per truck. It also brings natural resistance to decay and pests, which supports longer service life in real‑world conditions without purchasing more mats.

Fleet experience and case studies show these mats holding up under sustained heavy loads, mud, and traffic with little to no attrition over multi‑year runs. That’s what matters once mats leave the brochure and hit the right‑of‑way. That durability is what underpins lower total cost of ownership: fewer failures, fewer replacements, and fewer freight moves over the life of the asset.

As owners and contractors push for both lower costs and lower impact, Eucalyptus offers a practical way to do both at once. Plantation‑grown fiber, higher strength‑to‑weight, and longer life all contribute to lower carbon per job and less pressure on USA natural hardwood forests. Choosing Eucalyptus mats is ultimately a business decision, but for many projects it is one of the rare choices that improves safety and reliability on site while also moving environmental metrics in the right direction

Frequently Asked Questions

What is Eucalyptus, and where is it predominantly found?

Eucalyptus is a genus that includes over 700 species of flowering trees and shrubs, primarily native to Australia.

What are the benefits of Eucalyptus for ground protection applications?

Eucalyptus trees are known for their rapid growth and adaptability, making them beneficial for ground protection. Their timber is strong, durable, and lightweight, ideal for construction and utility projects.

How do Eucalyptus mats contribute to ground protection?

Eucalyptus mats create a stable surface for heavy machinery and vehicles, reducing soil compaction and minimizing environmental disruption.

How do Eucalyptus mats compare in strength to other types of wood?

Mats made from Eucalyptus Eucalyptus trees are to 40% stronger than #1 oak and up to 200-300% stronger than various mixed hardwoods.

What is the lifespan of Eucalyptus mats, and what are the advantages of using them?

Eucalyptus mats have a lifespan of 5-7 years with minimal loss. They are a cost-effective investment for enhancing safety and reducing replacement and maintenance costs.

What guarantee does World Forest Group offer for Eucalyptus mats?

World Forest Group provides a 10-point Manufacturing Guarantee, ensuring consistent quality and reliability of their products.

How do the characteristics of Eucalyptus raw material facilitate their use in utility projects?

The unique characteristics of Eucalyptus fiber allow for easier handling and transportation, which is essential for logistical efficiency in utility projects.

What feedback have customers provided regarding Eucalyptus mats?

Customer endorsements highlight the exceptional performance of Eucalyptus mats in extreme conditions, with reports indicating they can save tens of thousands of dollars per project.